- English

- Cymraeg

- icelandic

- беларускі

- Hrvatski

- Кыргыз тили

- Maori

- Монгол хэл

- Тоҷикӣ

- O'zbek

- Lëtzebuergesch

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- český

- ελληνικά

- український

- فارسی

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Slovenský jazyk

- Eesti Keel

- Română

- Slovenski

- Srpski језик

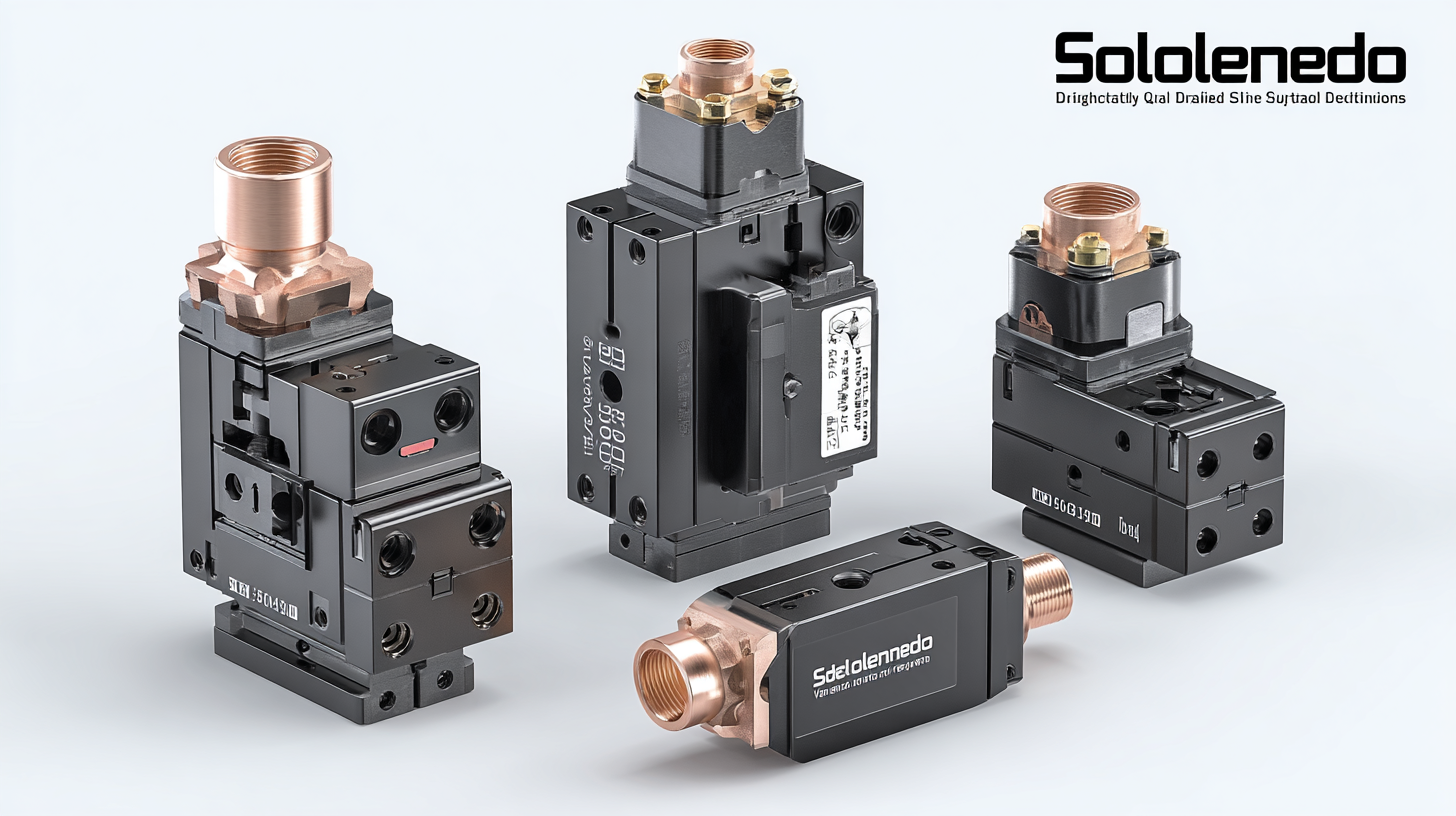

Solenoid directional valves play a crucial role in various industries, facilitating the control of fluid flow in hydraulic and pneumatic systems. In manufacturing alone, the global solenoid valve market is expected to reach

Solenoid directional valves play a crucial role in various industries, facilitating the control of fluid flow in hydraulic and pneumatic systems. In manufacturing alone, the global solenoid valve market is expected to reach