- English

- Cymraeg

- icelandic

- беларускі

- Hrvatski

- Кыргыз тили

- Maori

- Монгол хэл

- Тоҷикӣ

- O'zbek

- Lëtzebuergesch

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- český

- ελληνικά

- український

- فارسی

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Slovenský jazyk

- Eesti Keel

- Română

- Slovenski

- Srpski језик

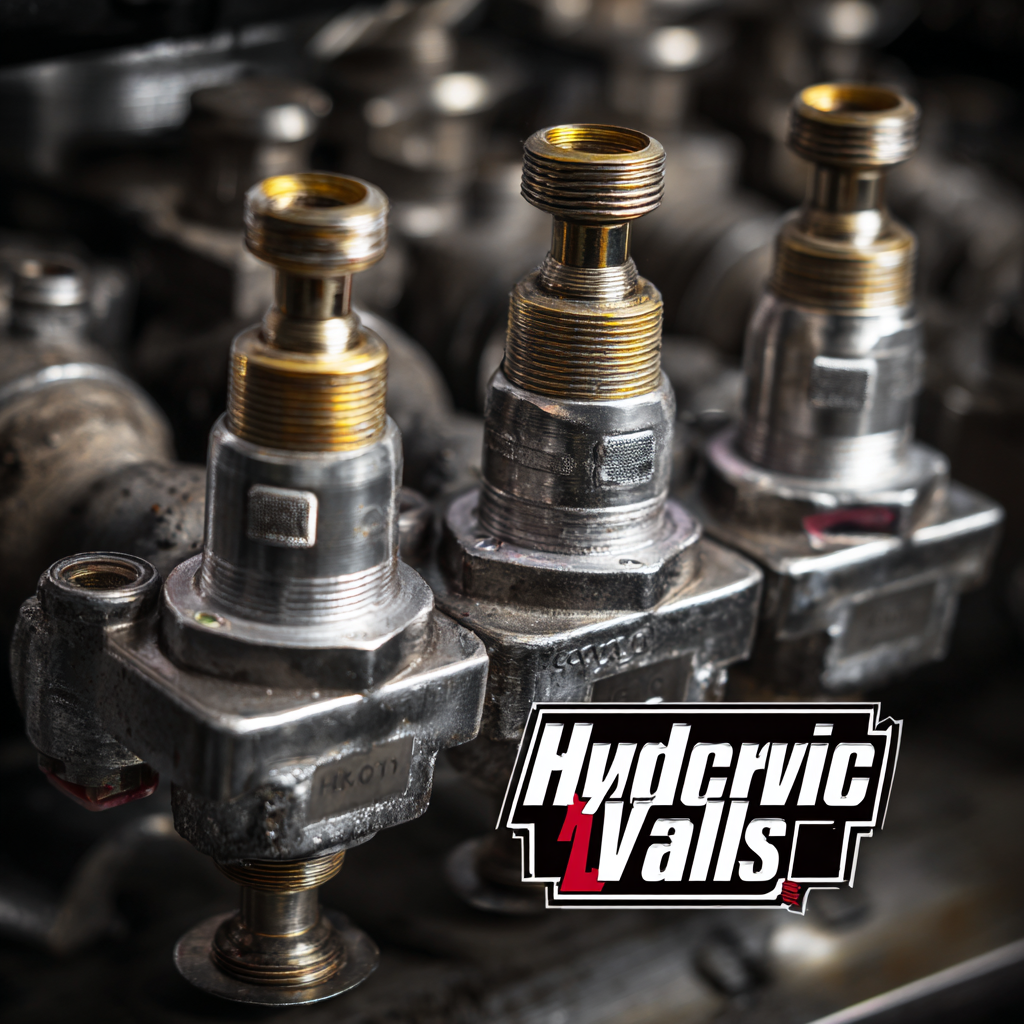

Hydraulic valves, specifically, are at the heart of controlling fluid flow and pressure, making their selection paramount to system performance. However, the process of choosing the best hydraulic valves can often be fraught with challenges, ranging from compatibility issues to performance inconsistencies. This blog will unravel ten essential tips that can help engineers and system designers overcome these challenges and select hydraulic valves that not only meet their operational needs but also contribute to the overall effectiveness of their hydraulic systems.

Hydraulic valves, specifically, are at the heart of controlling fluid flow and pressure, making their selection paramount to system performance. However, the process of choosing the best hydraulic valves can often be fraught with challenges, ranging from compatibility issues to performance inconsistencies. This blog will unravel ten essential tips that can help engineers and system designers overcome these challenges and select hydraulic valves that not only meet their operational needs but also contribute to the overall effectiveness of their hydraulic systems.

The flow rate determines how much hydraulic fluid can pass through the system and is typically measured in gallons per minute (GPM) or liters per minute (LPM). Choosing a valve that matches the specific flow requirements of your application will ensure optimal performance and efficiency, preventing issues like overheating or fluid turbulence that can compromise the system's integrity.

The flow rate determines how much hydraulic fluid can pass through the system and is typically measured in gallons per minute (GPM) or liters per minute (LPM). Choosing a valve that matches the specific flow requirements of your application will ensure optimal performance and efficiency, preventing issues like overheating or fluid turbulence that can compromise the system's integrity.