Global Trust in Quality: Discover China's Leading Best Solenoid Directional Valves

In today's rapidly evolving industrial landscape, Solenoid Directional Valves play a pivotal role in enhancing automation efficiency and precision. According to a report by Market Research Future, the global solenoid valve market is projected to reach USD 5.62 billion by 2027, growing at a compound annual growth rate (CAGR) of 5.5% from 2020. This surge demonstrates an increasing reliance on these critical components across various sectors, including automotive, manufacturing, and healthcare.

As a frontrunner in the global market, China offers a diverse range of high-quality solenoid directional valves that cater to stringent industry standards. With innovative designs and advanced manufacturing technologies, Chinese manufacturers are poised to meet the growing demand for reliable and efficient hydraulic and pneumatic solutions. This article will delve into the key features and benefits of China's leading solenoid directional valves, highlighting why global industries are placing their trust in these exceptional products.

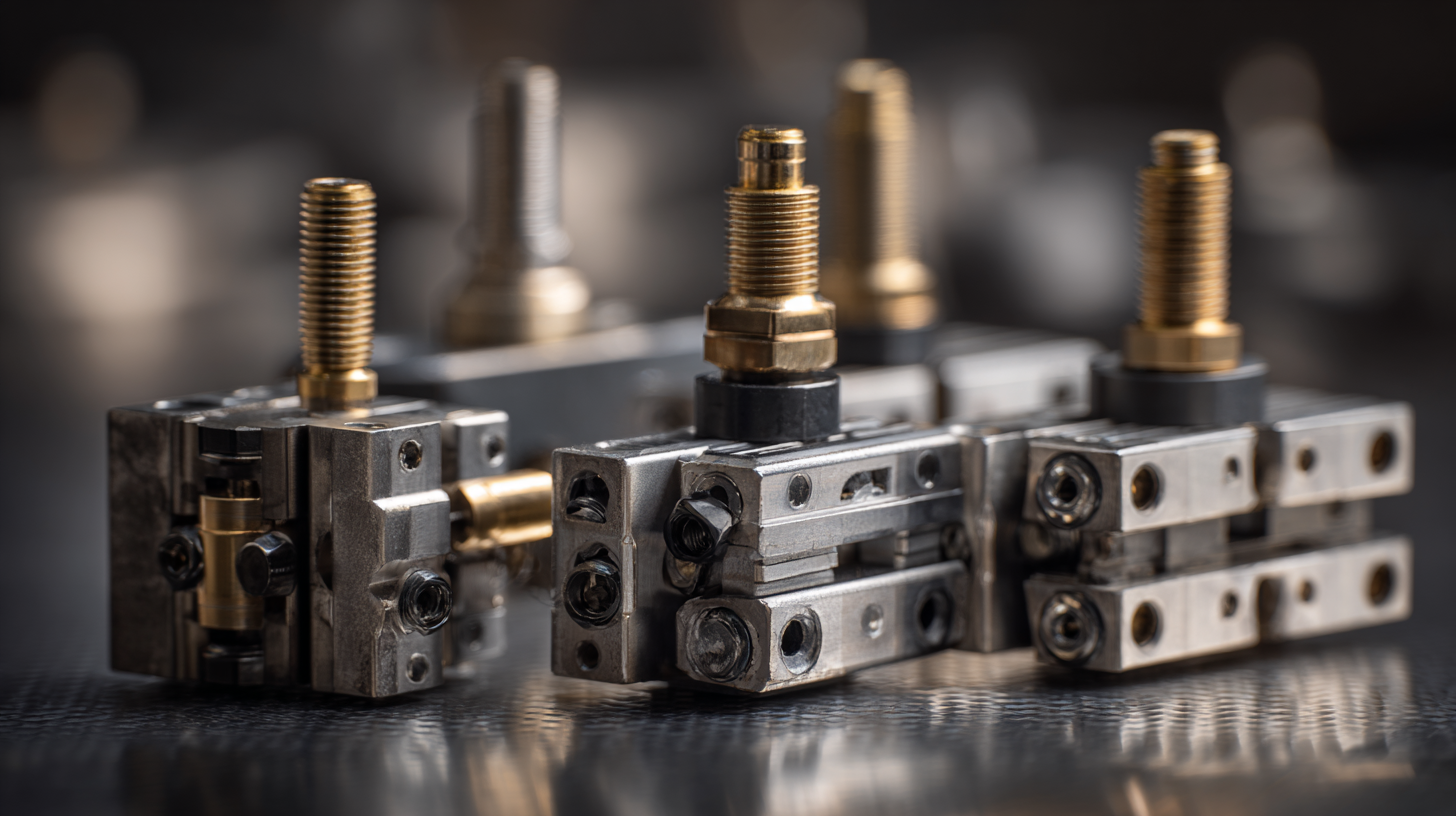

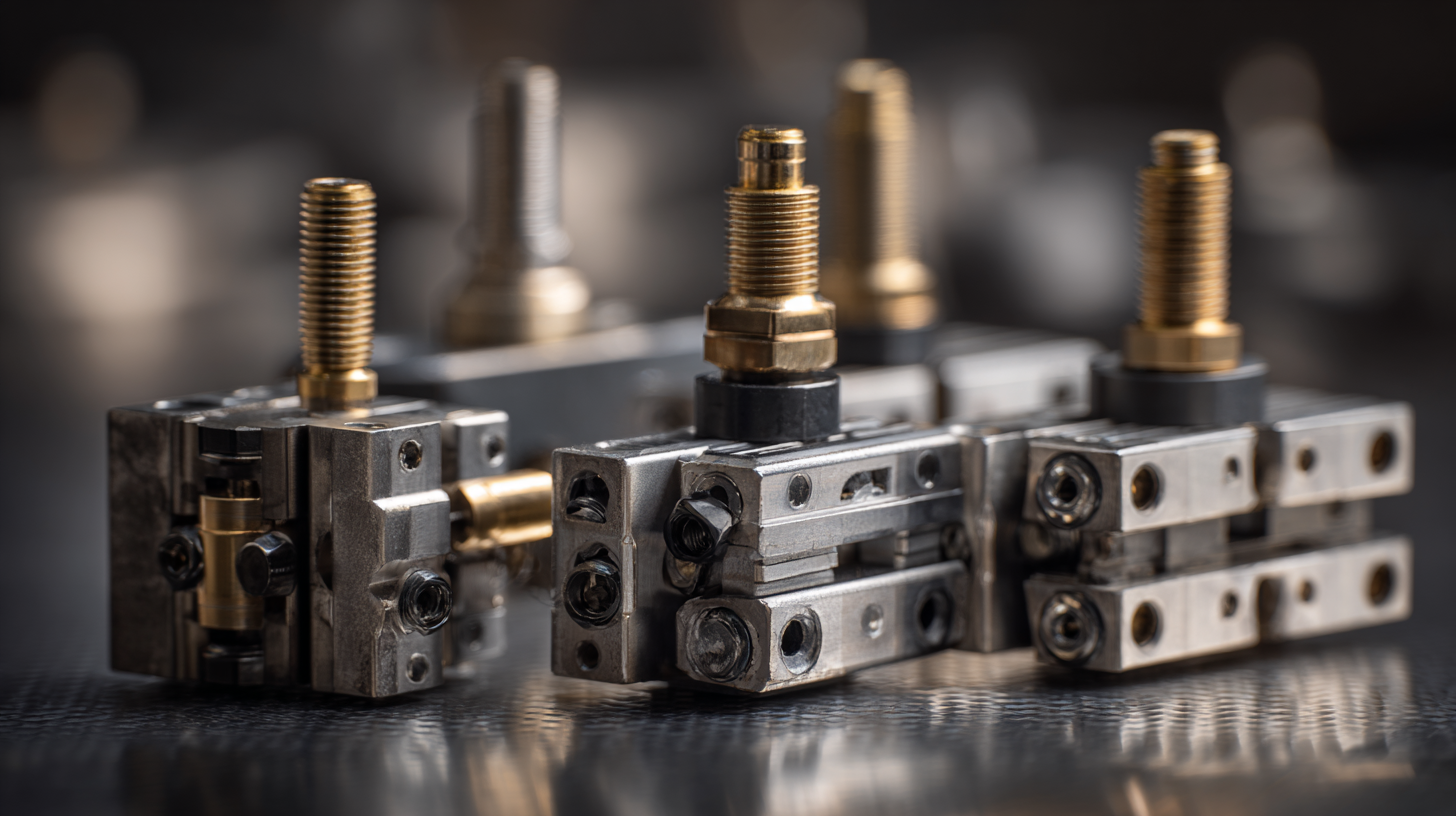

Identifying Key Features of High-Quality Solenoid Directional Valves

When searching for high-quality solenoid directional valves, several key features must be prioritized to ensure optimal performance and longevity. The construction material is critical; valves made of durable materials such as brass, stainless steel, or specialized plastics can withstand harsher environments and resist corrosion over time. Furthermore, attention should be given to the valve's sealing mechanism, as robust seals prevent leaks and maintain pressure stability, which is crucial in both industrial and commercial applications.

Tips: Look for additional certifications that guarantee compliance with international standards, as these can signify a manufacturer’s commitment to quality. Another essential feature is the response time of the solenoid. A quicker response time generally indicates a higher efficiency of operation, which can significantly impact the overall effectiveness of your system.

Additionally, consider the voltage and electrical specifications of the solenoid valves. Choosing the right voltage not only affects compatibility with your existing system but also affects energy consumption, allowing for greater efficiency. Before making a purchase, it’s beneficial to consult datasheets and user reviews to ensure the valve meets your specific requirements and expectations.

Evaluating Manufacturer Credentials and Industry Reputation

When evaluating the manufacturers of solenoid directional valves in China, it is crucial to examine their credentials and industry reputation. Trust is the cornerstone of quality manufacturing; therefore, manufacturers with a robust history of compliance with international standards tend to stand out. Companies that have earned certifications such as ISO 9001 or those recognized for their adherence to quality management practices often indicate a commitment to excellence in production. Investigating these credentials can provide insights into a manufacturer’s operational efficiency and reliability.

Additionally, industry reputation plays a significant role in identifying the top players in the market. Customer reviews, testimonials, and case studies can all shed light on a manufacturer’s track record. Engaging with industry forums and networks can further authenticate claims of quality and performance. A reputable manufacturer not only produces high-quality solenoid directional valves but also prioritizes customer service and technical support. By focusing on these critical elements, businesses can make informed decisions and select manufacturers that can meet their high standards for quality and trustworthiness in the competitive landscape of solenoid valve production.

Global Trust in Quality: Discover China's Leading Best Solenoid Directional Valves - Evaluating Manufacturer Credentials and Industry Reputation

| Manufacturer Location |

Production Capacity (Units/Month) |

Certification (ISO, CE, etc.) |

Years in Operation |

Specialization Area |

Customer Ratings (Out of 5) |

| Shanghai |

50,000 |

ISO 9001, CE |

15 |

Hydraulic Systems |

4.5 |

| Beijing |

30,000 |

ISO 14001, CE |

10 |

Pneumatic Control |

4.7 |

| Guangzhou |

40,000 |

ISO 9001 |

20 |

Industrial Automation |

4.6 |

| Shenzhen |

60,000 |

ISO 9001, CE, RoHS |

25 |

Marine Applications |

4.8 |

Understanding Different Types of Solenoid Directional Valves and Their Applications

Solenoid directional valves are essential components in various hydraulic and pneumatic systems, providing precise control over fluid flow. These valves operate by using electromagnetic forces to switch the flow path, making them highly efficient for automated systems. There are several types of solenoid directional valves, including 2-way, 3-way, and 4-way valves, each suited for specific applications. For example, 2-way valves are ideal for simple on/off control, while 3-way valves can facilitate exhaust flow in addition to the main flow, and 4-way valves are crucial for controlling double-acting cylinders.

In industrial settings, the applications of solenoid directional valves are vast, ranging from robotics and automotive to manufacturing equipment. Industries utilize these valves for tasks such as controlling actuators that require precise positioning and speed regulation. China's leading solenoid directional valve manufacturers have positioned themselves as global players by focusing on quality and innovation. By understanding the different types and their respective applications, engineers and designers can make informed choices that enhance system efficiency and reliability.

Best Practices for Assessing Performance and Durability in Valves

In the rapidly evolving landscape of industrial valves, the demand for high-quality solenoid directional valves is on the rise. As the HPLC check valve market is projected to reach $21.27 million in 2024 and soar to $34.93 million by 2032, an impressive growth rate of 6.39% is expected. This trend highlights the increasing importance of assessing performance and durability in valve manufacturing.

To ensure that products meet international quality standards, manufacturers should implement best practices for testing and evaluation. This includes rigorous performance assessments that focus on reliability under various operating conditions. Additionally, durability tests should simulate extended use, providing valuable insights into the lifespan of these components. By adhering to these practices, companies can enhance product credibility, ensuring their solenoid directional valves are not only efficient but also resilient in demanding applications.

Performance and Durability Assessment of Solenoid Directional Valves

Exploring Innovative Solutions for Optimizing Valve Functionality in China

In the fast-evolving landscape of valve technology, China's innovation in solenoid directional valves stands out as a beacon of quality and performance. The recent exhibition at Flowtech China (Shanghai) showcased how manufacturers are pushing the boundaries of valve functionality. These advancements are not merely incremental improvements; they represent a significant shift towards adopting innovative solutions that enhance the efficiency and reliability of industrial processes. By leveraging cutting-edge technologies and precision engineering, these companies are committed to optimizing flow control and responding to the growing demands of various applications.

One remarkable trend is the integration of advanced materials and smart technologies into valve design. These innovative approaches not only improve the durability and functionality of solenoid valves but also contribute to sustainability efforts within the industry. The ongoing research into materials, including bioactive scaffolds inspired by tissue engineering principles, highlights the potential for cross-disciplinary collaborations that can lead to breakthroughs in valve performance. As the industry continues to evolve, China’s leadership in producing high-quality solenoid directional valves will play a pivotal role in shaping the future of fluid control technologies globally.