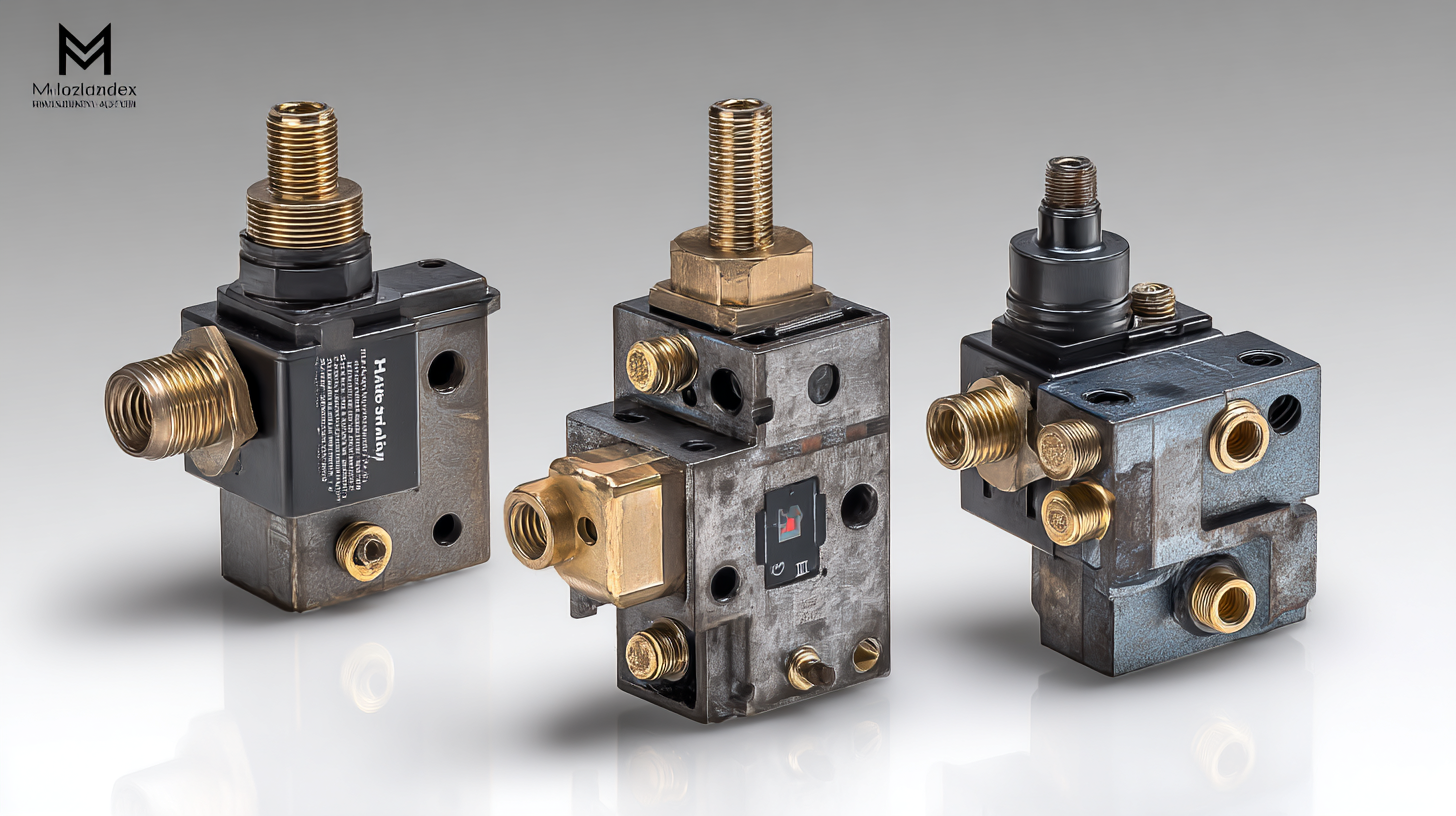

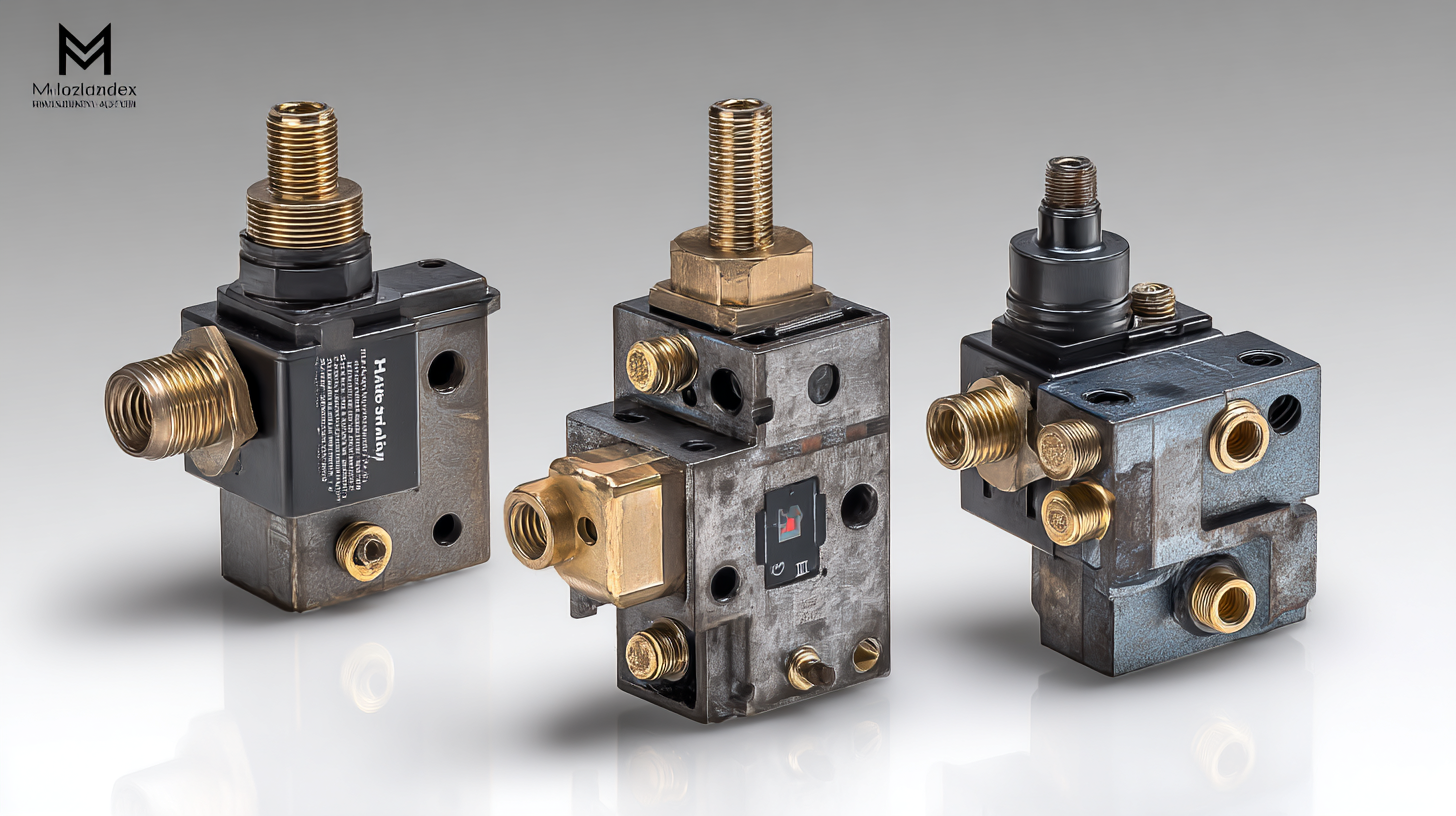

Innovative Solutions for Achieving Optimal Performance with Best Hydraulic Valves

In the ever-evolving landscape of industrial machinery, achieving optimal performance is paramount, and hydraulic valves play a crucial role in this pursuit. According to recent reports from the International Fluid Power Society, the global market for hydraulic valves is expected to reach $12 billion by 2025, driven by advancements in automation and the increasing demand for high-efficiency systems. Utilizing innovative solutions for hydraulic valves not only maximizes system efficiency but also enhances overall operational reliability. This blog will explore essential tips and strategies to select and implement the best hydraulic valves, ensuring that industries can harness the full potential of these vital components. From understanding flow control principles to integrating smart technologies, we will uncover actionable insights that lead to improved performance and cost savings in hydraulic systems.

Emerging Trends in Hydraulic Valve Technology for Enhanced Performance

The hydraulic valve technology sector is witnessing significant advancements, driven by the need for enhanced performance in industrial applications. As the Global Industrial Hydraulic Equipment Market is projected to reach USD 52.6 billion by 2033, at a 5.7% CAGR, it highlights a growing demand for innovative hydraulic solutions. Emerging trends show that manufacturers are increasingly focused on integrating metal additive manufacturing techniques, which have revolutionized hydraulic component design. This approach not only enhances performance but also promotes sustainability by minimizing waste and allowing for more complex geometries in valve design.

Moreover, the successful evolution of proportional valves indicates a marked shift towards addressing the demands of more complex applications. With improved features aimed at greater connectivity and precision, these valves are becoming indispensable in various industrial settings that require accurate control and efficiency. Concurrently, the rise in the Electro Hydraulic Servo Valve (EHSV) market further underscores an industry push towards precision and reliability, ensuring that hydraulic systems can meet the ever-growing challenges of modern machinery and heavy-duty mobile equipment. This intersection of technological innovation and market demand is set to redefine the landscape of hydraulic valve performance in the upcoming years.

Understanding Hydraulic Valve Mechanisms and Their Impact on System Efficiency

Hydraulic valves play a crucial role in the efficiency and functionality of hydraulic systems. Understanding their mechanisms is essential for optimizing performance. Hydraulic valves function as control devices that govern the flow and pressure of hydraulic fluid. By adjusting the fluid's path, these valves can influence the speed and power of hydraulic actuators, ensuring that machinery operates smoothly and effectively.

The types of hydraulic valves—such as directional control, pressure relief, and flow control valves—each serve specific functions that, when utilized appropriately, can significantly enhance system efficiency.

Moreover, the impact of hydraulic valve mechanisms extends beyond mere control; they can improve energy consumption and reduce wear and tear on components. Efficient valve design minimizes fluid resistance and energy loss, allowing systems to run at optimal performance levels. For instance, proportional valves provide precise control over flow rates, which can lead to smoother operations and prolong equipment lifespan.

As industries seek to innovate and improve their hydraulic systems, investing in high-quality hydraulic valves and understanding their intricate mechanisms can lead to substantial gains in productivity and cost savings.

Key Performance Indicators for Selecting Hydraulic Valves: A Data-Driven Approach

When it comes to selecting hydraulic valves, a data-driven approach offers clarity and precision, ensuring optimal performance.

Key Performance Indicators (KPIs) such as response time, pressure rating, and flow coefficient need to be meticulously analyzed.

According to a recent study by the Hydraulic Institute, 85% of hydraulic system failures can be traced back to component selection, underscoring the importance of making informed choices.

Hydraulic valves must be evaluated based on their ability to regulate flow and pressure, ensuring that systems operate within safe and efficient parameters.

When it comes to selecting hydraulic valves, a data-driven approach offers clarity and precision, ensuring optimal performance.

Key Performance Indicators (KPIs) such as response time, pressure rating, and flow coefficient need to be meticulously analyzed.

According to a recent study by the Hydraulic Institute, 85% of hydraulic system failures can be traced back to component selection, underscoring the importance of making informed choices.

Hydraulic valves must be evaluated based on their ability to regulate flow and pressure, ensuring that systems operate within safe and efficient parameters.

Tip: Always assess the intended application of the hydraulic valve. Specific metrics such as maximum and minimum operating pressures can help determine the suitability of a valve for your system.

Moreover, effective benchmarking against industry standards plays a crucial role in performance evaluation.

For example, a report from the International Journal of Fluid Power indicates that valves with a high flow coefficient (Cv) can significantly enhance energy efficiency.

Selecting valves with optimal Cv ratings can reduce energy consumption by up to 30% in hydraulic systems.

Tip: Regularly consult updated performance data and trends in technology advancements to stay ahead in your selection process and ensure your systems are utilizing the most efficient components available.

Case Studies: Successful Implementation of Advanced Hydraulic Valves in Industry

In various industries, the implementation of advanced hydraulic valves has proven to be transformative, enhancing efficiency and performance. Case studies highlight how companies have successfully integrated innovative hydraulic solutions into their operations. For example, a leading manufacturing plant noticed a significant reduction in energy consumption after switching to high-efficiency hydraulic valves. This change not only cut costs but also improved the longevity of machinery, showcasing the profound impact of selecting the right components.

When considering new hydraulic valves, it's essential to focus on compatibility with existing systems. Assessing the flow requirements and the operational environment will guide you toward the most suitable options. Additionally, investing in valves with smart features can provide real-time data, allowing for proactive maintenance and minimizing downtime.

Another critical aspect is training personnel on the new systems to ensure they understand the operational benefits and maintenance protocols. Proper training can enhance the overall effectiveness of the hydraulic system, ultimately contributing to improved productivity and optimal performance across the board.

Innovative Solutions for Achieving Optimal Performance with Best Hydraulic Valves - Case Studies: Successful Implementation of Advanced Hydraulic Valves in Industry

| Application |

Valve Type |

Industry |

Performance Improvement (%) |

Reduction in Downtime (Hours) |

Cost Savings ($) |

| Mobile Equipment |

Directional Control Valve |

Construction |

15 |

10 |

7500 |

| Manufacturing Automation |

Pressure Relief Valve |

Manufacturing |

20 |

5 |

10000 |

| Water Management |

Ball Valve |

Utilities |

13 |

8 |

6000 |

| Marine Applications |

Check Valve |

Marine |

18 |

12 |

9000 |

| Pharmaceutical Production |

Solenoid Valve |

Pharmaceutical |

25 |

3 |

12000 |

Future Outlook: Innovations Shaping the Hydraulic Valve Market in the Next Decade

The hydraulic valve market is on the brink of a transformative decade, driven by innovations in technology and a growing emphasis on efficiency. According to a recent report by MarketsandMarkets, the global hydraulic valve market is projected to reach approximately $8 billion by 2028, growing at a CAGR of 4.5% from 2023. Key advancements such as IoT integration and smart valve technology are set to revolutionize performance and maintenance protocols, offering manufacturers the ability to monitor valve performance in real time and make data-driven decisions.

Tip: When considering hydraulic valves, focus on solutions that incorporate predictive maintenance features. This technology not only reduces downtime but also extends the life of the components, ultimately leading to significant cost savings.

Moreover, sustainability is becoming a critical driver in the hydraulic valve sector. The push for environmentally friendly manufacturing processes, alongside the adoption of energy-efficient systems, is reshaping production methodologies. The emergence of bio-degradable fluids and the incorporation of lightweight materials are steps toward reducing the carbon footprint of hydraulic systems.

Tip: Always choose hydraulic valves designed for energy efficiency. Not only do they benefit the environment, but they also enhance the operational performance of machinery, ensuring that you stay ahead of the competition.

When it comes to selecting hydraulic valves, a data-driven approach offers clarity and precision, ensuring optimal performance.

Key Performance Indicators (KPIs) such as response time, pressure rating, and flow coefficient need to be meticulously analyzed.

According to a recent study by the Hydraulic Institute, 85% of hydraulic system failures can be traced back to component selection, underscoring the importance of making informed choices.

Hydraulic valves must be evaluated based on their ability to regulate flow and pressure, ensuring that systems operate within safe and efficient parameters.

When it comes to selecting hydraulic valves, a data-driven approach offers clarity and precision, ensuring optimal performance.

Key Performance Indicators (KPIs) such as response time, pressure rating, and flow coefficient need to be meticulously analyzed.

According to a recent study by the Hydraulic Institute, 85% of hydraulic system failures can be traced back to component selection, underscoring the importance of making informed choices.

Hydraulic valves must be evaluated based on their ability to regulate flow and pressure, ensuring that systems operate within safe and efficient parameters.