Understanding the Technical Specifications of Best Proportional Valves for Optimal Performance

In the realm of industrial automation and fluid control, Proportional Valves play a pivotal role in enhancing system efficiency and performance. According to a recent market analysis by Research and Markets, the global proportional valve market is projected to reach $3.3 billion by 2025, indicating a robust growth driven by advancements in technology and increasing demand across various sectors.

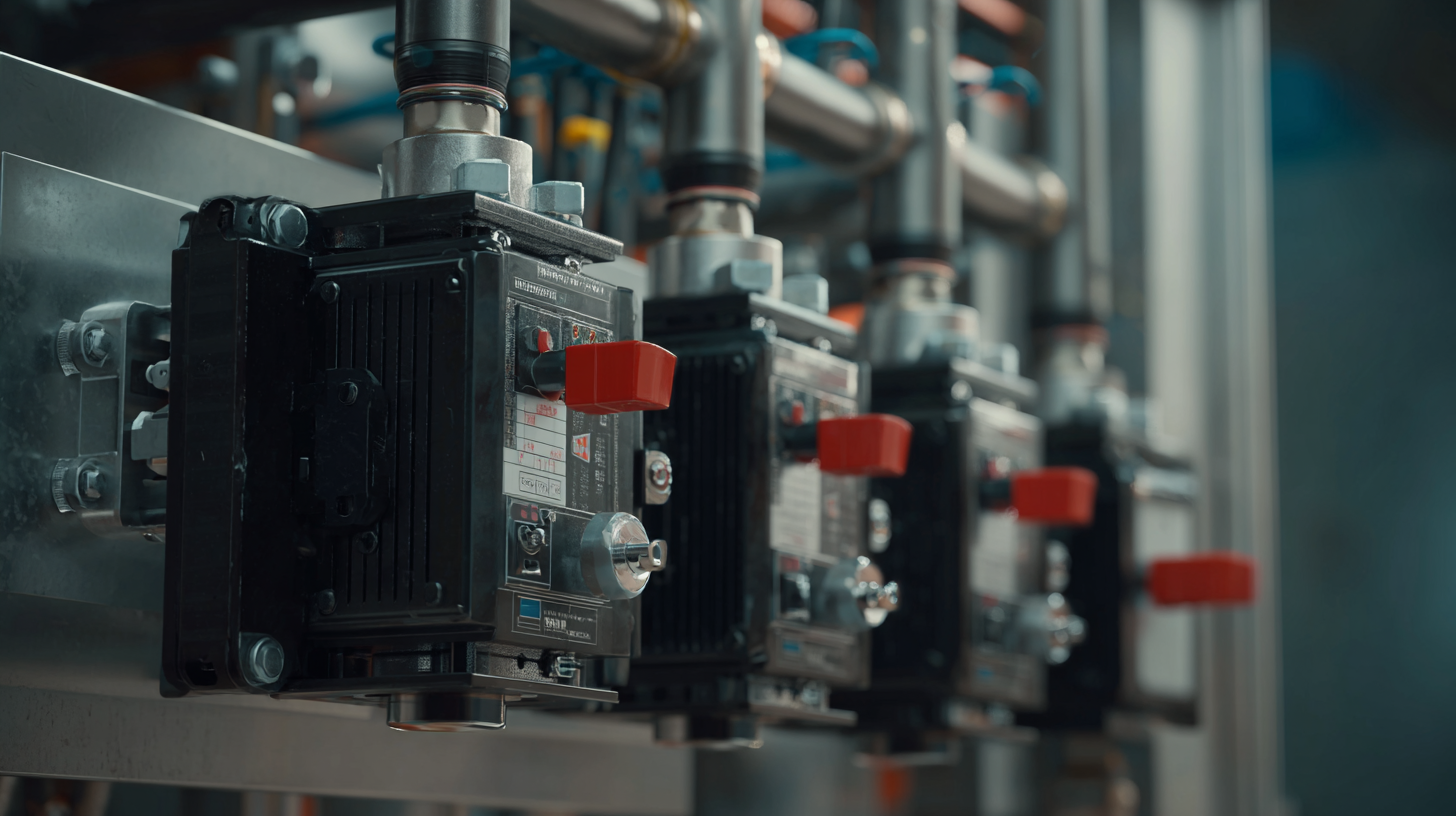

These valves, renowned for their ability to precisely control fluid flow, pressure, and direction, are essential in applications ranging from manufacturing to aerospace. As industries continue to seek optimization and reliability, understanding the technical specifications of the best proportional valves becomes crucial.

It is imperative to recognize that not all valves are created equal; therefore, sourcing from top manufacturers, particularly those emerging from China's leading factories, becomes essential for ensuring optimal performance and building global trust in industrial solutions.

Key Features to Consider in Proportional Valves for Enhanced Control

Proportional valves play a crucial role in enhancing control in various fluid power systems, primarily through their ability to adjust flow and pressure with high precision. Key features to consider when selecting a proportional valve include response time, stability, and robustness. Recent studies highlight significant advancements, such as the development of a fractional-order proportional-integral-derivative (FOPID) controller designed specifically for pneumatic control valves. This innovative approach promises ultra-low overshoot and rapid response, which is essential for applications requiring tight control, such as robotics and automation systems.

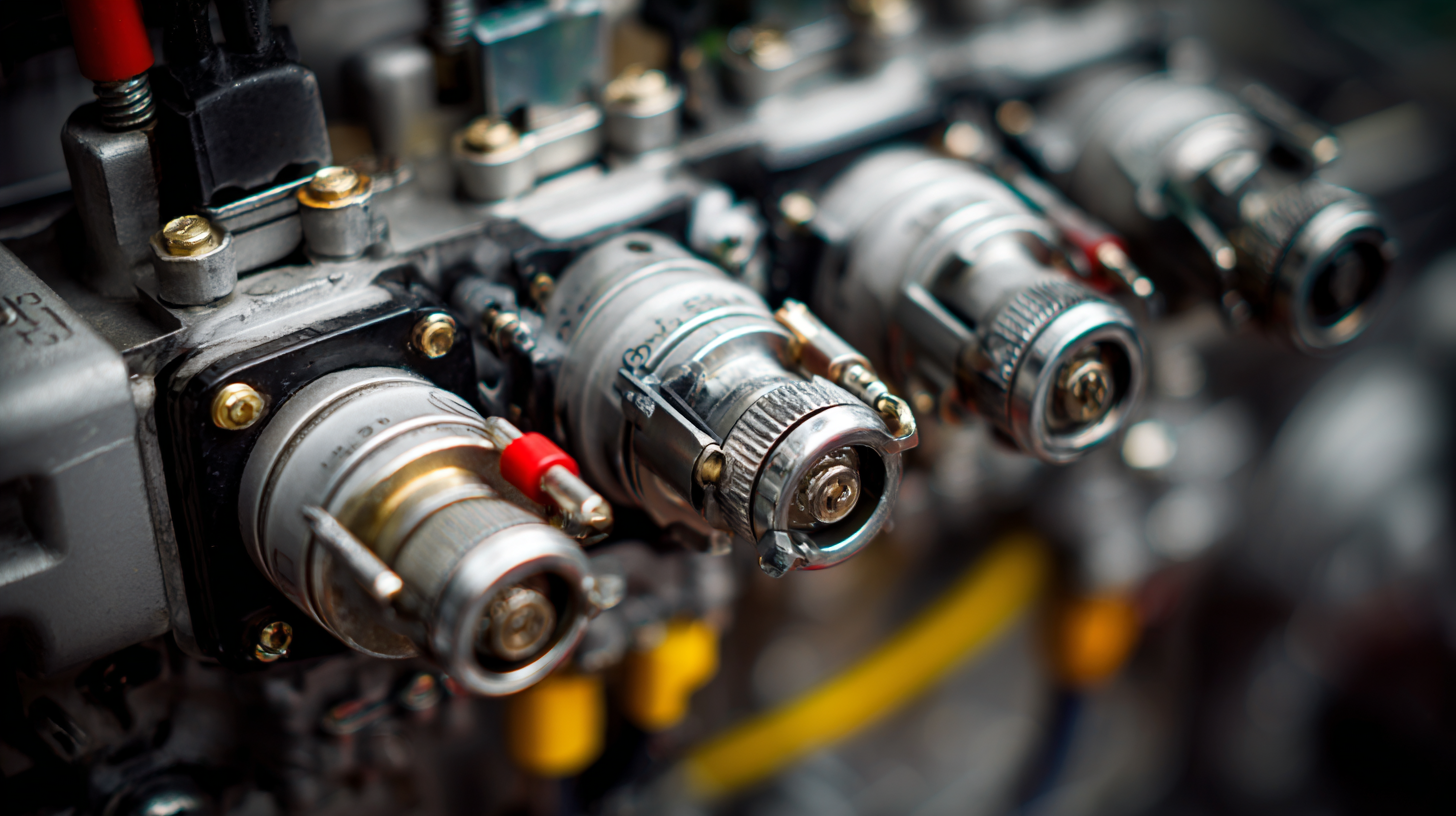

Further, the integration of piezoelectric technology has shown to enhance the performance of pneumatic control, adding to the versatility of proportional valves. For instance, the deployment of advanced electrohydraulic servo valves is expected to grow significantly, with market reports projecting increased demand owing to their improved precision and efficiency. As industries increasingly recognize the advantages of direct-operated solenoid valves, the market is likely to witness a shift toward more compact and highly responsive systems, making them suitable for complex applications like articulated cranes and vibration control systems.

Comparing Different Types of Proportional Valve Designs and Their Uses

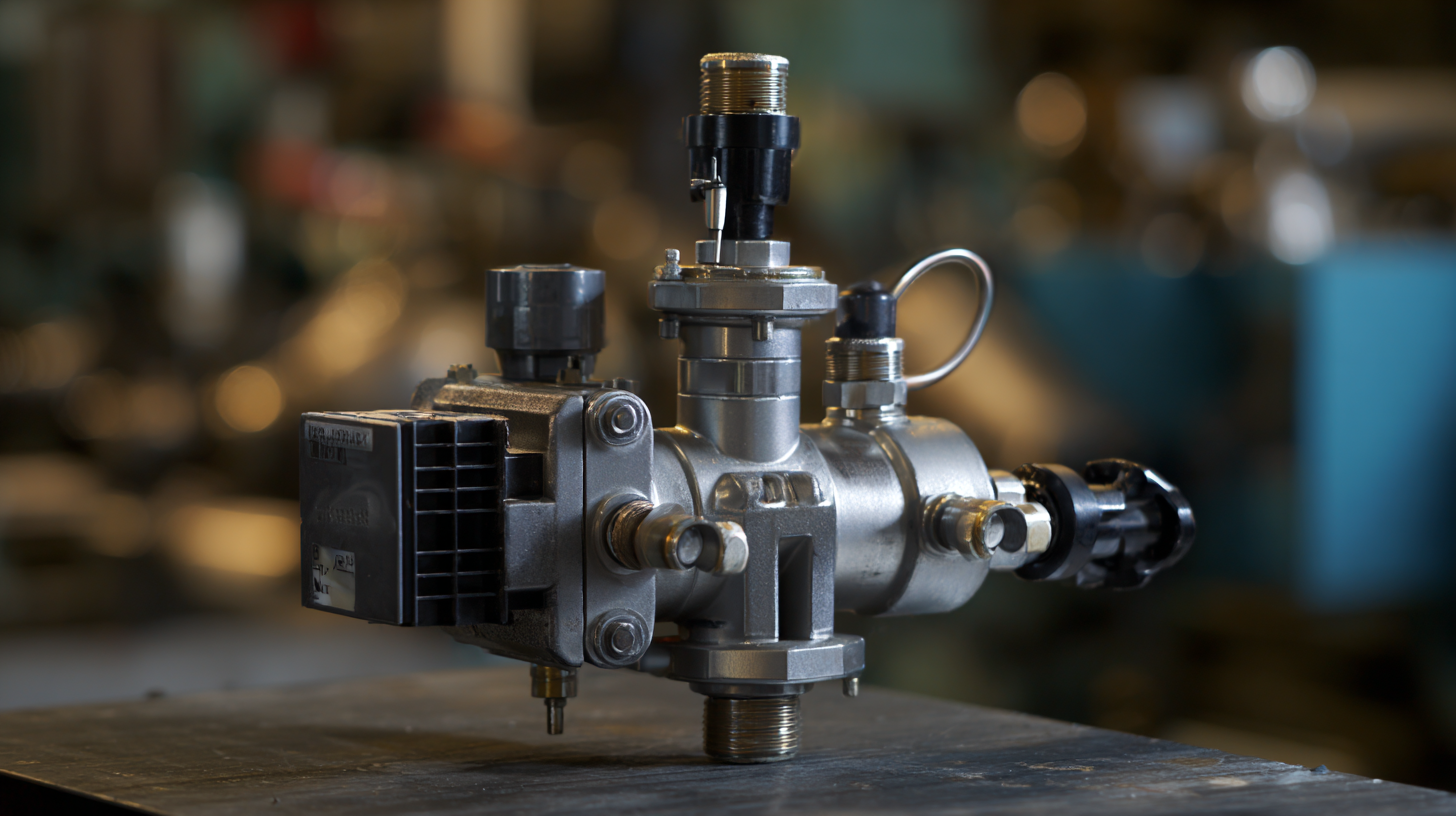

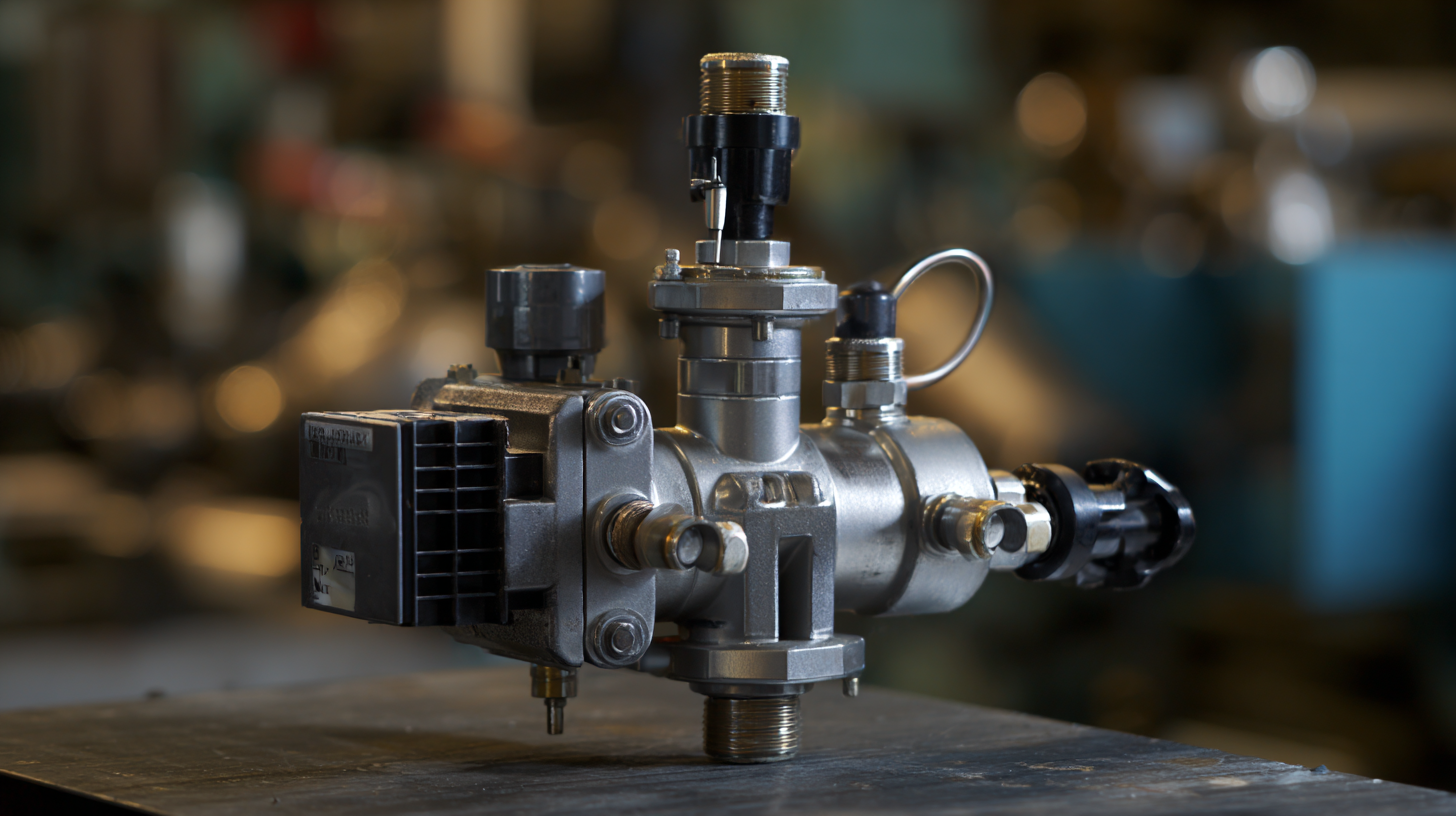

Proportional valves play a crucial role in hydraulic fluid power systems, widely utilized across various engineering domains, including transportation, heavy industry, and robotics. Among the different types of proportional valve designs, two notable categories are servo valves and solenoid-operated proportional valves. Servo valves offer high precision control and are often employed in applications that require rapid response times and fine-tuning, such as aerospace and advanced robotics. In contrast, solenoid-operated proportional valves are more common in less critical applications due to their simpler design and lower cost, making them suitable for general industrial uses.

Recent advancements in valve technology have resulted in the development of novel designs that enhance the performance and controllability of hydraulic systems. For example, integrating miniaturized valves into pneumatic systems has significantly improved the efficiency of fluidically actuated soft robots. A study highlighted that by adopting these new valve designs, engineers can achieve dynamic flow balance, which is essential for optimizing the operation under varying pressure conditions. Reports indicate that leveraging advanced proportional valve designs can lead to improved response times by up to 25%, making them invaluable for applications requiring agility and precision in fluid control.

Comparative Analysis of Proportional Valve Types

Understanding Flow Characteristics and Pressure Ratings for Optimal Performance

When selecting proportional valves, understanding flow characteristics is crucial for achieving optimal performance in various applications. The flow characteristics of a valve define how it responds to changes in pressure and how it regulates the fluid movement through the system. Proportional valves are designed to provide a precise control of flow rates, which is essential in applications such as hydraulic systems, where accurate positioning and speed control are paramount. By analyzing the valve's flow curves, engineers can determine how the valve behaves under different operating conditions, ensuring that it meets the specific needs of the system.

Additionally, pressure ratings play a significant role in the performance of proportional valves. Each valve is designed to withstand certain pressure limits, which are vital for preventing failures during operation. Understanding the pressure ratings helps in selecting the right valve for intense applications where high pressure is a common factor. It’s important for engineers to ensure that the chosen valve not only meets the flow requirements but also fits within the pressure constraints of the system. By considering both flow characteristics and pressure ratings, one can select the best proportional valve that not only optimizes performance but also enhances the reliability and longevity of the entire hydraulic system.

The Importance of Material Selection in Proportional Valve Durability

When selecting materials for proportional valves, durability is a critical factor that can significantly impact performance. The choice of material directly influences the valve's resistance to wear, corrosion, and pressure fluctuations, which are common in high-stress applications. According to a recent industry report, lightweight materials such as aluminum alloys and high-strength steels are increasingly favored for their superior strength-to-weight ratios and enhanced performance characteristics. This trend is mirrored in the automotive sector, where advancements in material science have led to the development of next-generation vehicles that prioritize efficiency and structural integrity.

Moreover, material selection can determine the lifespan and reliability of proportional valves. For instance, the incorporation of advanced polymer composites and coatings can offer additional protection against the harsh operating environments these valves typically endure. Reports indicate that valves made from such robust materials can last up to 30% longer in demanding applications compared to those made from conventional metals. Hence, investing in the right material not only ensures optimal valve performance but also contributes to overall system efficiency, ultimately leading to a reduction in operational costs over time.

Common Applications of Proportional Valves Across Various Industries

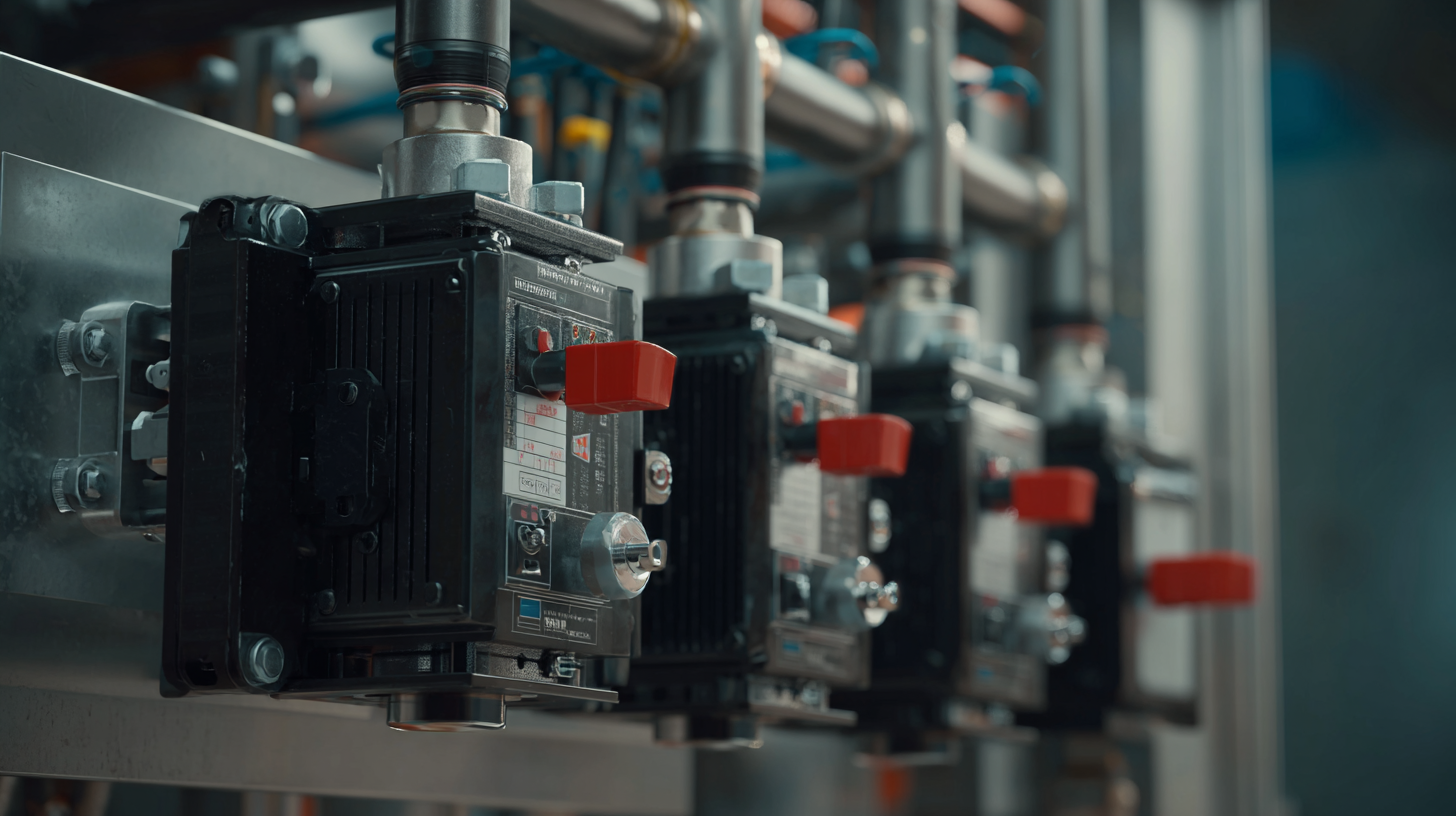

Proportional valves play a crucial role in various industries by offering precise control over fluid flow, which is essential for optimal system performance. These valves are increasingly being used in applications ranging from aerospace to energy and automation sectors. With the rise in demand for automation and energy efficiency, the functionality and design of proportional valves are evolving rapidly. Recent innovations have led to the development of smarter hydraulic valves that are capable of delivering high power capacity and enhanced durability, meeting the stringent requirements of modern applications.

When considering proportional valves for industrial use, it’s essential to prioritize features that enhance performance. Look for valves with advanced connectivity options, allowing for seamless integration with digital systems. Additionally, evaluate the durability of the valve’s design, especially in high-stress environments, to ensure long-term reliability.

Investing in proper training for staff on the operation and maintenance of these valves can significantly improve system efficiency. Understanding the unique applications of proportional valves in different sectors will aid in selecting the right type for specific needs, ensuring optimal performance across the board. Keep abreast of market trends and technological advancements to take full advantage of the capabilities these valves offer.

Understanding the Technical Specifications of Best Proportional Valves for Optimal Performance - Common Applications of Proportional Valves Across Various Industries

| Industry |

Typical Applications |

Key Specifications |

Performance Characteristics |

| Manufacturing |

Automated assembly lines, CNC machines |

Flow rate: 10-60 L/min, Pressure rating: 210 bar |

High precision control, Fast response time |

| Agriculture |

Hydraulic control for irrigation systems |

Flow rate: 15-80 L/min, Pressure rating: 200 bar |

Energy efficient, Durable under harsh conditions |

| Automotive |

Brake systems, Power steering |

Flow rate: 5-40 L/min, Pressure rating: 180 bar |

Responsive actuation, Low noise operation |

| Construction |

Excavators, Loaders |

Flow rate: 20-90 L/min, Pressure rating: 250 bar |

Robust construction, High load capacity |

| Robotics |

Motion control, Automated guided vehicles |

Flow rate: 1-30 L/min, Pressure rating: 160 bar |

Precision motion control, Compact design |